In modern transportation infrastructure, SS Expanded Mesh (stainless steel expanded mesh) has emerged as a key material in protective barriers, safety fencing, and isolation systems. Its unique combination of strength, durability, and design flexibility makes it a superior choice for highways, railways, bridges, airports, and urban road networks. This article explores the core advantages of ss Expanded Mesh in transportation facilities and explains why it has become the material of choice for long-term safety and cost efficiency.

1. Core Advantages of ss Expanded Mesh in Transportation Facilities

High strength and impact resistance

SS expanded mesh is formed by stamping and stretching cold-rolled or hot-rolled stainless steel sheets, creating a seamless three-dimensional mesh structure without weak welded joints. This process results in excellent overall rigidity, enabling the mesh to withstand strong impacts, such as vehicle collisions, and effectively prevent road crossing and falling object accidents. On highways, for instance, SS expanded mesh is widely used for anti-glare panels that diffuse headlight beams, improving night driving safety.

Long-lasting durability and low maintenance

The lifespan of SS expanded mesh is a key advantage in transportation applications. While galvanized steel mesh typically lasts 10 to 15 years, stainless steel expanded mesh—especially grades like 304 or 316L—can provide reliable service for 30 to 50 years. Its corrosion resistance eliminates the need for frequent maintenance or replacement, reducing long-term costs. Furthermore, its modular design allows for rapid installation, cutting construction time by over 50% compared to concrete barriers.

Functional integration

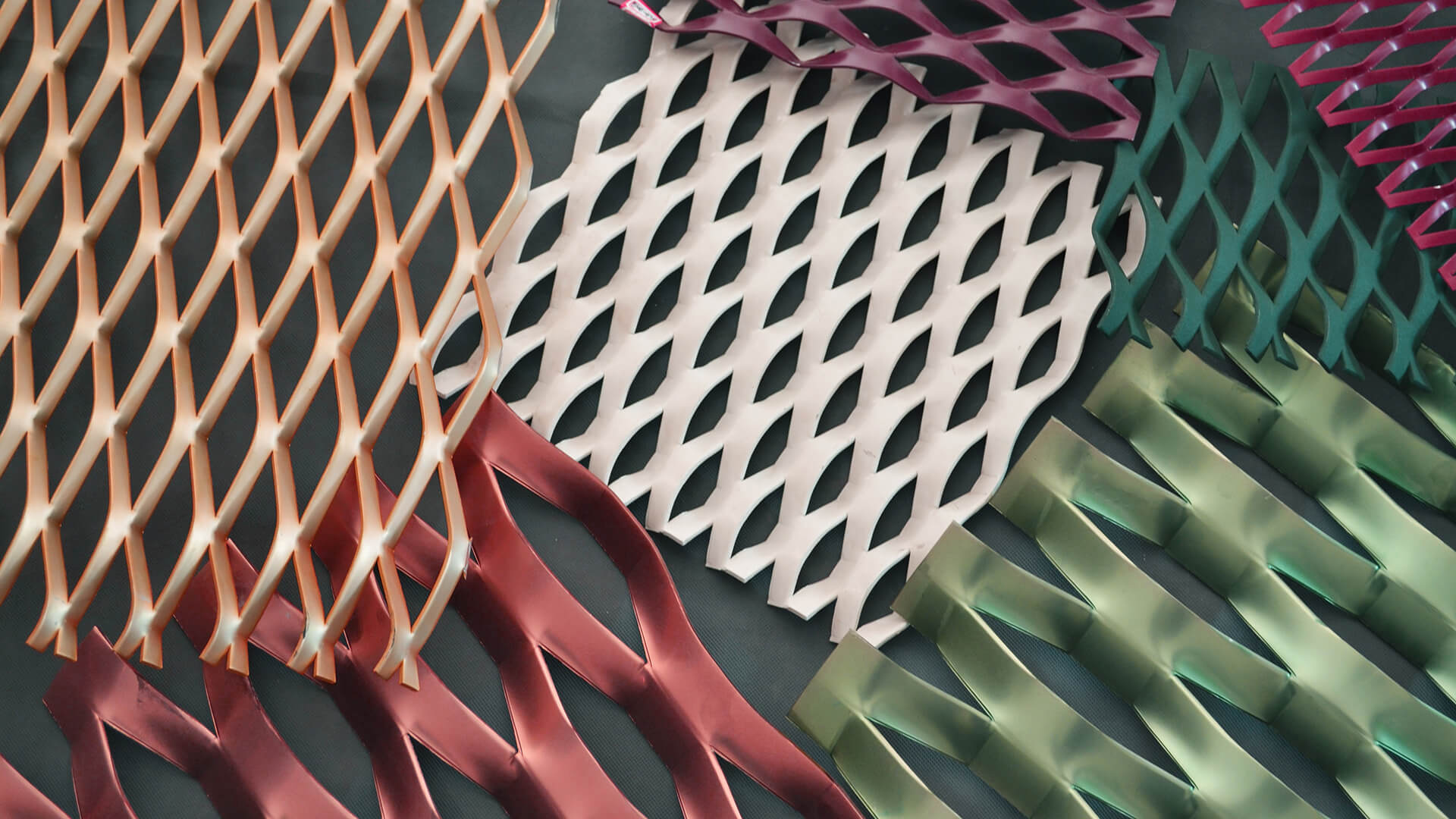

Beyond its protective function, SS expanded mesh offers several added benefits. Its open design allows light and air to pass through, maintaining visibility and reducing wind resistance on bridges and elevated structures. The mesh can be customized in diamond, hexagonal, or circular patterns to meet specific project needs such as noise reduction, anti-throwing measures, or anti-glare requirements. Its lightweight nature—approximately one-third the weight of concrete guardrails—reduces foundation load and simplifies installation on complex structures.

2. Stainless Steel Expanded Mesh vs. Other Materials

SS expanded mesh outperforms alternative materials in several critical areas:

Corrosion resistance

-

SS expanded mesh: ★★★★★ Excellent rust resistance, even in harsh coastal or industrial environments

-

Galvanized steel mesh: ★★★ Limited resistance, typically 5-8 years before corrosion appears

-

Welded wire mesh: ★★ Prone to rust and weld failure

-

Concrete guardrail: ★★★★ Durable but susceptible to weathering

Strength and rigidity

-

ss Expanded Mesh: ★★★★ High tensile strength (>500 MPa), excellent impact resistance

-

Galvanized steel mesh: ★★★ Adequate, but requires thicker material for similar strength

-

Welded wire mesh: ★★ Deforms easily under stress

-

Concrete guardrail: ★★★★ High rigidity but brittle under impact

Environmental adaptability

-

SS expanded mesh: ★★★★★ Performs well in saline, acidic, and high-humidity environments

-

Galvanized steel mesh: ★★ Limited resistance in coastal or humid regions

-

Welded wire mesh: ★ Only suitable for dry environments

-

Concrete guardrail: ★★★ General-purpose but limited flexibility

Life cycle cost

-

SS expanded mesh: ★★★★ Higher upfront cost, but minimal maintenance and long service life reduce total cost

-

Galvanized steel mesh: ★★★ Requires periodic anti-corrosion maintenance

-

Welded wire mesh: ★ Frequent replacements needed

-

Concrete guardrail: ★★★ High cost for repairs

Aesthetics and customization

-

SS expanded mesh: ★★★★★ Supports complex designs, polished finishes, and architectural integration

-

Galvanized steel mesh: ★★★ Functional but plain appearance

-

Welded wire mesh: ★ Limited aesthetics, prone to coating failure

-

Concrete guardrail: ★★ Basic and bulky

3. Why Choose HIGHTOP SS Expanded Mesh for Transportation Facilities

HIGHTOP offers SS expanded mesh solutions that meet the highest industry standards:

-

Superior materials: 304/316L stainless steel with thicknesses from 0.5 mm to 8 mm, delivering 30% higher tensile strength

-

Precision manufacturing: Stamping accuracy with mesh uniformity (error ≤ 0.1 mm), ensuring structural integrity

-

Design flexibility: Custom diamond, hexagonal, or circular patterns, sizes up to 2 m wide and 4 m long

-

Fast delivery: Over 200 tons in stock for mainstream specifications, orders shipped within 48 hours

-

Cost efficiency: Large-scale production lowers unit price by 10-15% versus competitors, with pre-cut and edged panels reducing on-site waste

4. Setting New Safety Standards with SS Expanded Mesh

SS expanded mesh has evolved from a protective material to a multi-functional component that enhances safety, aesthetics, and cost-efficiency in transportation facilities. With its corrosion resistance, long lifespan, and design versatility, it offers unparalleled value for highways, bridges, railways, and airports. HIGHTOP’s tailored solutions ensure your projects achieve maximum safety, durability, and return on investment.

For long-term protection and performance, choose HIGHTOP SS expanded mesh. Contact us today for customized solutions that meet your exact project needs!

Get in Touch

Please Email us via the contact form below, we will get back to you ASAP.