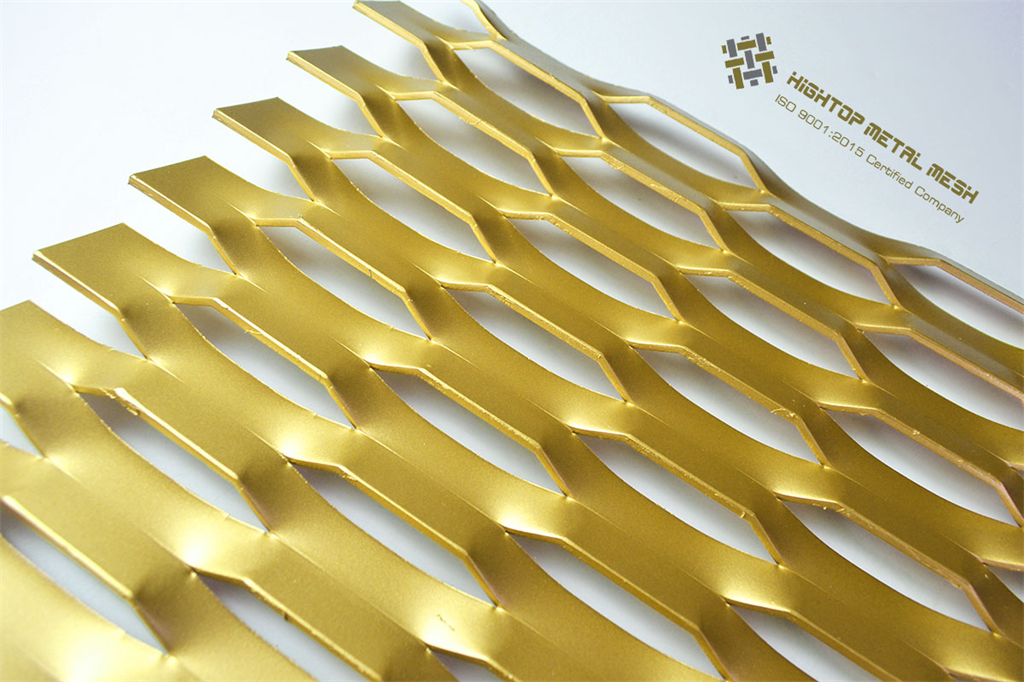

When selecting materials for decorative and functional applications, aesthetics and durability often stand as the top priorities. Among the wide variety of metals available today, Brass Expanded Metal distinguishes itself as a premium choice. This material is produced by stamping and stretching brass sheets—typically alloys such as 270 brass, composed of about 65% copper and 35% zinc. The result is a mesh that combines mechanical strength with a warm golden appearance, making it an attractive solution for projects that demand both performance and visual appeal.

Characteristics, Advantages, and Limitations

Brass Expanded Metal offers a balance of properties that make it suitable for both architectural and industrial use. Its mechanical properties provide strength and hardness with a smooth mesh surface and high friction coefficient, which is valuable for flooring, platforms, or protective mesh applications. At the same time, brass is easier to cut, form, and process compared to harder metals like steel.

In terms of corrosion resistance, brass performs well in a variety of environments, resisting wear and degradation over time. However, in high-humidity or high-temperature settings, it may oxidize, leading to changes in surface appearance. This effect can be minimized with protective finishes or proper material selection. One important factor is avoiding traditional brass with high lead content, which can cause both safety and environmental concerns. Instead, modern lead-free or low-lead alloys such as ECObrass provide sustainable alternatives that meet international safety standards.

While brass offers unique benefits, it is not without limitations. It lacks the extreme strength of stainless steel, can deform under heavy impact, and has a relatively lower melting point, limiting its suitability for high-temperature industrial processes. Furthermore, due to its high copper content, brass is generally more expensive than alternative materials. This higher cost means it is best applied in projects where its distinctive look and properties add significant value.

Architectural and Decorative Applications

One of the most prominent uses of Brass Expanded Metal is in architectural design and interior decoration. Its golden hue brings a sense of warmth and elegance that cannot be replicated by other metals. Hotels, shopping centers, and upscale residences often incorporate it into lobby partitions, wall panels, ceilings, railings, and door trims. Beyond its aesthetic value, its durability ensures that these installations remain visually appealing for many years without the fading or aging issues common with wood or plastic alternatives.

When compared to stainless steel expanded metal, brass has a decorative advantage thanks to its rich color, even though stainless steel offers superior strength and corrosion resistance. Aluminum alloy grilles, while lightweight and corrosion-resistant, often lack the luxurious texture of brass. Likewise, wood or plastic materials may provide cost savings but fall short in terms of longevity, safety, and fire resistance.

For designers seeking both artistic flair and lasting quality, Brass Expanded Metal stands out as a material that brings beauty and functionality together.

Industrial and Functional Applications

Although often associated with decorative use, Brass Expanded Metal is equally valuable in high-end industrial contexts. It can be applied to machinery platforms, walkways, and escalators where its strength, slip resistance, and durability add safety and reliability. In addition, its excellent electrical conductivity makes it an effective solution for radio-frequency interference (RFI) shielding in electronic devices. High-end audio equipment manufacturers often choose brass mesh for speaker grilles due to both its sound transparency and striking appearance.

Compared with mild steel or galvanized steel mesh, brass offers greater resistance to corrosion and superior aesthetic qualities. Plastic alternatives, on the other hand, cannot withstand high temperatures or heavy loads, limiting their usefulness in demanding environments. In cases where both performance and visual impact matter, brass is often the most comprehensive solution.

Special Applications

The versatility of Brass Expanded Metal also extends to unique fields such as art installations and public safety. Artists value its ductility and golden tone for creating sculptural works, while industries rely on its slip resistance for applications such as tanker truck footrests. These examples highlight its adaptability across industries that value form as much as function.

Why Choose HIGHTOP Brass Expanded Metal?

At HIGHTOP, we provide premium Brass Expanded Metal with an emphasis on safety, sustainability, and customization. Our products are crafted from lead-free or low-lead alloys, ensuring compliance with international standards and supporting environmentally conscious projects. Advanced manufacturing technology guarantees precise mesh patterns, smooth surfaces, and reliable mechanical properties.

Customers can choose from a wide range of mesh sizes, thicknesses, and finishes, including glossy, brushed, and antique bronze styles, making it possible to tailor every detail to match design goals. Beyond manufacturing, our team offers professional consultation to guide clients toward the most suitable material for their applications.

Brass Expanded Metal is more than just a construction material—it is a design element that merges strength, durability, and elegance. While its higher cost may limit its use in some projects, its aesthetic warmth and functional versatility make it an irreplaceable option for applications that demand both beauty and long-term reliability. For architectural decoration, high-end industrial equipment, or artistic creation, this material consistently delivers superior results. Choosing Brass Expanded Metal ensures not only a premium finish but also a lasting investment in quality and performance.

Get in Touch

Please Email us via the contact form below, we will get back to you ASAP.