In modern construction, architecture, and industrial manufacturing, steel mesh materials must deliver far more than basic strength. Today’s projects demand durability, airflow, transparency, safety, and visual impact—often all at the same time. Diamond metal mesh, also commonly known as expanded metal mesh or stretched metal mesh, has become one of the most versatile and reliable solutions to meet these requirements.

HIGHTOP Wire Mesh, a professional Chinese steel mesh manufacturer with its own factory, specializes in producing high-quality diamond metal mesh for global customers across North America, Europe, and other international markets. With strong manufacturing capability, material flexibility, and export experience, HIGHTOP supplies diamond metal mesh that performs consistently across architectural, industrial, and infrastructure applications.

What Is Diamond Metal Mesh?

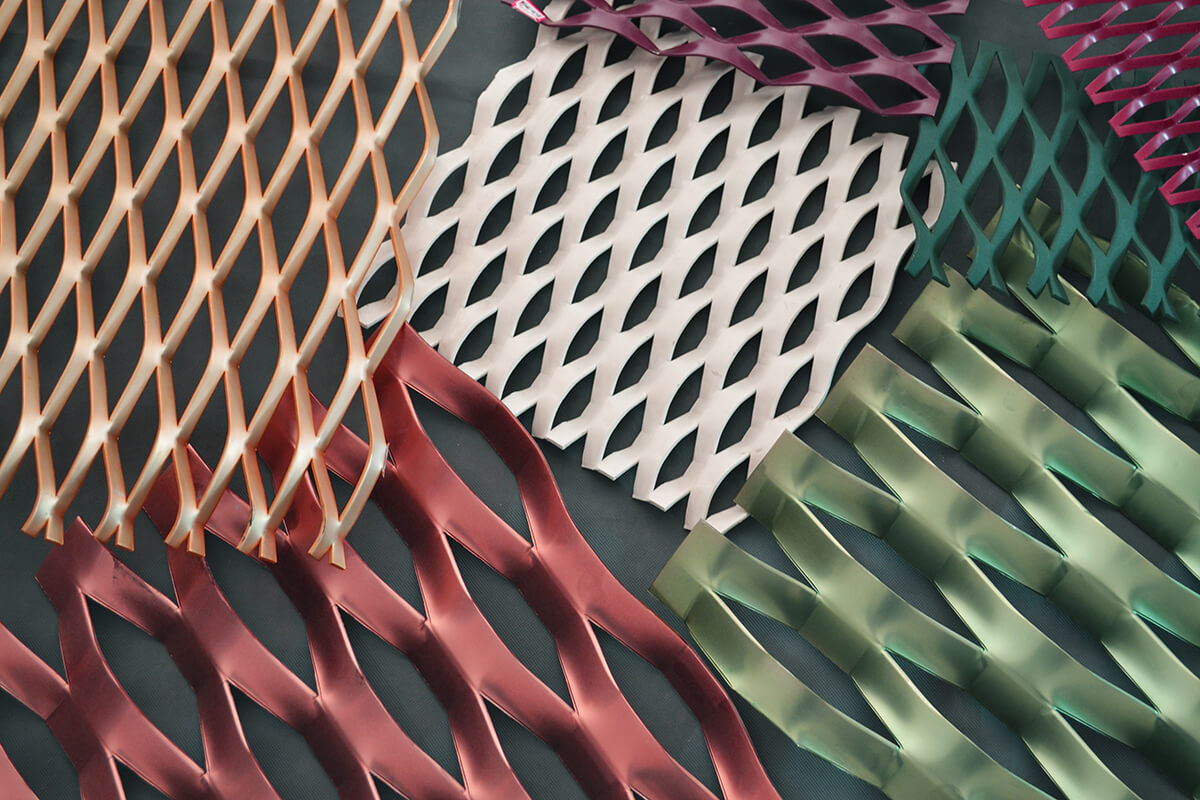

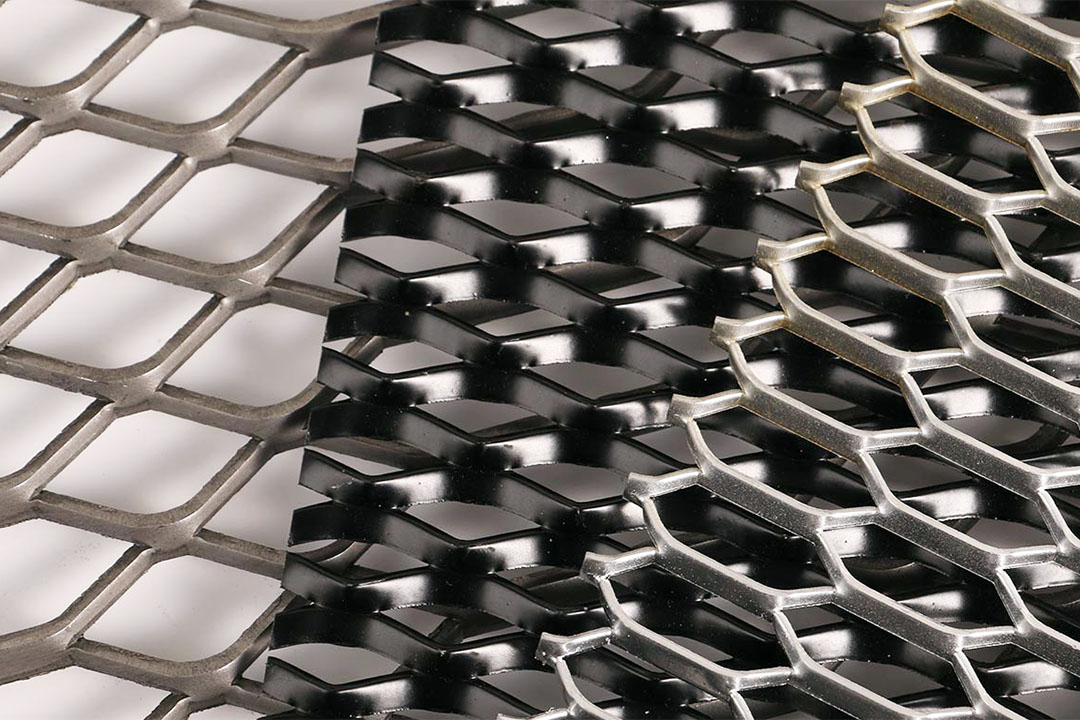

Diamond metal mesh is manufactured from a solid metal sheet that is precisely slit and stretched, rather than woven or welded. This process forms a continuous structure with uniform diamond-shaped openings, without generating scrap or waste. The result is a one-piece metal mesh with excellent structural integrity and a high strength-to-weight ratio.

Because the mesh is produced from a single sheet, all strands and bonds remain interconnected. This gives diamond metal mesh superior rigidity, impact resistance, and load-bearing capability compared to many alternative mesh types.

Materials Available for Diamond Metal Mesh

HIGHTOP offers diamond metal mesh in a wide range of materials to suit different performance and aesthetic requirements:

-

Carbon steel for strength and cost efficiency

-

Galvanized steel for corrosion resistance in outdoor environments

-

Stainless steel for harsh, corrosive, or long-term applications

-

Aluminum for lightweight architectural use

-

Copper and brass for decorative and specialty projects

Each material option allows customers to balance durability, appearance, and budget according to specific project needs.

Key Advantages of Diamond Metal Mesh

High Strength and Rigidity

The diamond-shaped pattern distributes force evenly across the mesh, creating a rigid structure that resists deformation while remaining lighter than solid metal sheets.

Efficient Material Utilization

The stretching process produces no scrap, making diamond metal mesh an efficient and environmentally responsible material choice.

Excellent Airflow and Visibility

Open diamond apertures allow air, light, heat, and sound to pass through freely, while still providing protection and structural support.

Long Service Life

With proper material selection and surface treatment, diamond metal mesh offers outstanding resistance to wear, impact, and corrosion, even in demanding industrial environments.

Typical Applications of Diamond Metal Mesh

Diamond metal mesh is widely used across architectural, industrial, and infrastructure projects, including:

- Building façades, sunshades, and decorative cladding

- Safety guards for machinery and equipment

- Industrial walkways, platforms, stair treads, and fire escapes

- Fencing, railings, and security panels

- Ventilation grilles, automotive grilles, and shelving systems

Its combination of strength, openness, and durability makes it suitable for both functional and design-driven applications.

Why Choose HIGHTOP Diamond Metal Mesh?

As a factory-direct manufacturer, HIGHTOP Wire Mesh offers:

- Consistent quality control throughout production

- Competitive pricing without intermediaries

- Customization in sheet size, thickness, opening size, and surface treatment

- Reliable delivery supported by strong production capacity

- Proven export experience for international projects

HIGHTOP’s diamond metal mesh is produced using precision equipment and strict quality standards to ensure stable performance across large-scale and repeat orders.

Frequently Asked Questions (FAQ)

What are the main uses of diamond metal mesh?

Diamond metal mesh is used in architectural cladding, safety barriers, machine guards, walkways, stair treads, fencing, ventilation panels, and decorative elements. Its strength and open structure make it suitable for both industrial and design-focused applications.

What are the advantages of diamond metal mesh?

The main advantages include high strength-to-weight ratio, excellent airflow and visibility, efficient material usage with no waste, strong impact resistance, and long service life. It is also highly adaptable to different materials and finishes.

Are there any disadvantages of diamond metal mesh?

Diamond metal mesh is more rigid than woven wire mesh, which may limit flexibility in certain fine filtration applications. Additionally, sharp edges may require finishing or edge treatment for safety in some uses.

How do I choose the right diamond metal mesh for my project?

Selection depends on application requirements such as load-bearing capacity, corrosion resistance, aesthetics, and budget. Material type, sheet thickness, strand width, and opening size should be matched to the operating environment and design goals. Consulting a manufacturer like HIGHTOP can help ensure the correct specifications.

With its balance of performance, durability, and visual appeal, diamond metal mesh continues to be a preferred solution for modern construction and industrial projects. HIGHTOP Wire Mesh remains committed to providing reliable products and professional manufacturing support to customers worldwide.

Get in Touch

Please Email us via the contact form below, we will get back to you ASAP.