In modern construction and industrial safety systems, the selection of materials directly impacts the durability, safety, and efficiency of projects. Among the many materials available, expanded metal stands out for its exceptional mechanical properties, adaptability, and long-term value. From scaffolding to curtain walls and equipment protection, it serves as a high-performance alternative to conventional materials like plastic, wood, or traditional wire mesh. This article explores the five core advantages of expanded metal and why it is a top choice for engineers and builders worldwide.

1. Outstanding Structural Strength and Safety Performance

One of the most significant advantages of expanded metal is its exceptional strength and resilience under pressure. Thanks to advancements in CNC stamping and laser cutting, modern expanded metal offers tensile strength exceeding 800MPa. This superior strength makes it ideal for high-load scenarios, such as curtain wall systems on high-rise buildings. For example, a 3mm galvanized expanded metal panel provides 40% more wind pressure resistance than traditional aluminum panels, all while reducing weight by 35%.

Furthermore, the diamond-shaped mesh structure efficiently disperses impact forces, offering additional protection against falling objects and punctures. This makes it especially valuable in temporary platforms and high-risk construction zones.

2. Exceptional Corrosion Resistance for Harsh Environments

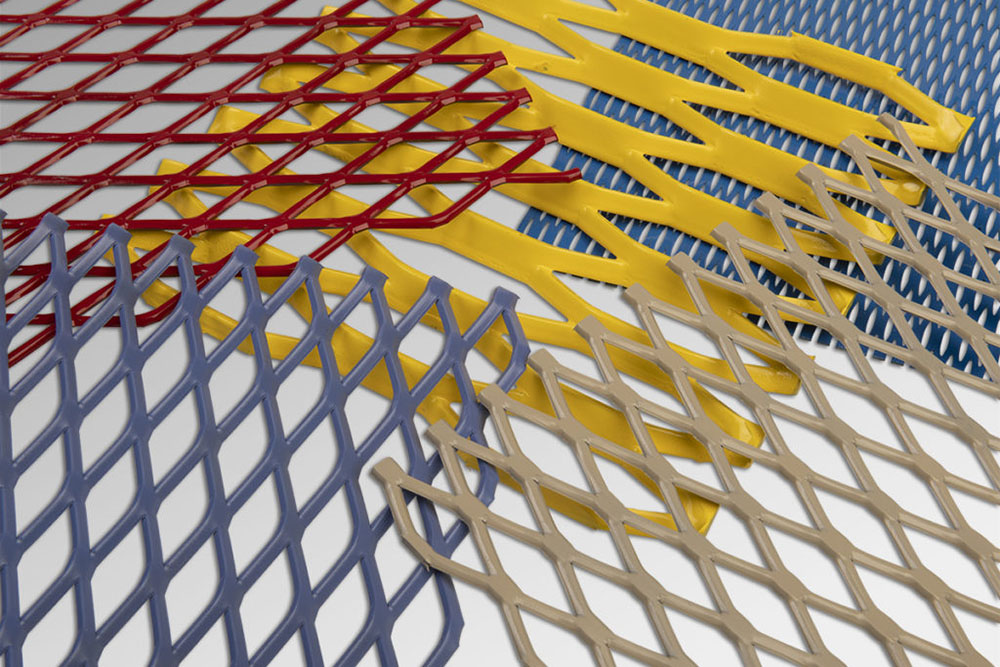

The longevity of expanded metal is another key advantage. With surface treatment options such as hot-dip galvanizing, PVC coating, and fluorocarbon spraying, it can endure challenging environments for over 25 years. In highly corrosive settings—like chemical plants or coastal infrastructure—304 or 316L stainless steel mesh provides a natural resistance to rust and chemical degradation.

Different grades and materials allow tailored applications. Whether for budget-friendly low-carbon steel or premium weather-resistant stainless steel, engineers can select mesh products based on the specific chemical and moisture exposure levels of each project.

3. Lightweight and Easy to Install

Despite its strength, expanded metal is remarkably lightweight. Its three-dimensional structure reduces overall material usage while maintaining structural integrity. Standard-sized panels can often be carried and installed by a single worker, which significantly speeds up construction. Compared to solid steel plates, installation times can be reduced by up to three times, leading to major cost savings on labor and equipment.

In addition, its open mesh design promotes airflow and light transmission—up to 80% in some cases—reducing the risk of heat buildup and improving visibility in confined workspaces. This not only enhances worker comfort but also increases safety in welding or enclosed environments.

4. Versatile Applications Across the Building Lifecycle

expanded metal is a multi-functional material with applications throughout the entire lifecycle of a building or infrastructure project. Its uses include:

Construction scaffolding: Lightweight and secure, it replaces bulky and dangerous wooden planks.

Structural reinforcement: Acts as a reliable support for anchors and grid systems.

Architectural decoration: Offers designers dynamic visual effects with customizable patterns for partitions and facades.

Long-term protection: Serves as robust, maintenance-free protection for bridges, equipment, and machinery.

This broad applicability makes expanded metal an all-in-one solution that adapts to various functional and aesthetic needs.

5. Sustainable and Economical Over the Long Term

expanded metal supports green building practices through both production efficiency and recyclability. Galvanized mesh is 100% recyclable, and each ton reused saves approximately 1.6 tons of CO₂ emissions compared to virgin steel. This aligns well with modern sustainability goals and qualifies for innovation points under many green building certification standards.

Additionally, the manufacturing process of steel mesh is energy-efficient, consuming as little as 380kWh per ton—roughly 30% less than traditional production methods. In use, its porous structure acts as a natural shading system, which can reduce air conditioning energy costs by up to 18%.

Why Choose expanded metal Over Traditional Alternatives?

Compared to traditional protective materials, expanded metal offers a clear advantage:

Versus wire mesh: Offers double the tensile strength, better weather resistance, and far fewer maintenance needs.

Versus wooden planks: Non-combustible, five times the load capacity, and resistant to rot and termites.

Versus plastic netting: Retains structural integrity from -30°C to 100°C, with 95% UV resistance.

These advantages make expanded metal a smart investment for any project that requires durability, safety, and longevity.

As a material, expanded metal has evolved from basic industrial use into a modern engineering solution that balances strength, aesthetics, and sustainability. Its ability to perform in extreme environments, coupled with its ease of installation and economic value, makes it an essential component in contemporary construction and industrial safety.

For professionals seeking a dependable, high-performance material, expanded metal represents the future of structural protection and design innovation.

Get in Touch

Please Email us via the contact form below, we will get back to you ASAP.