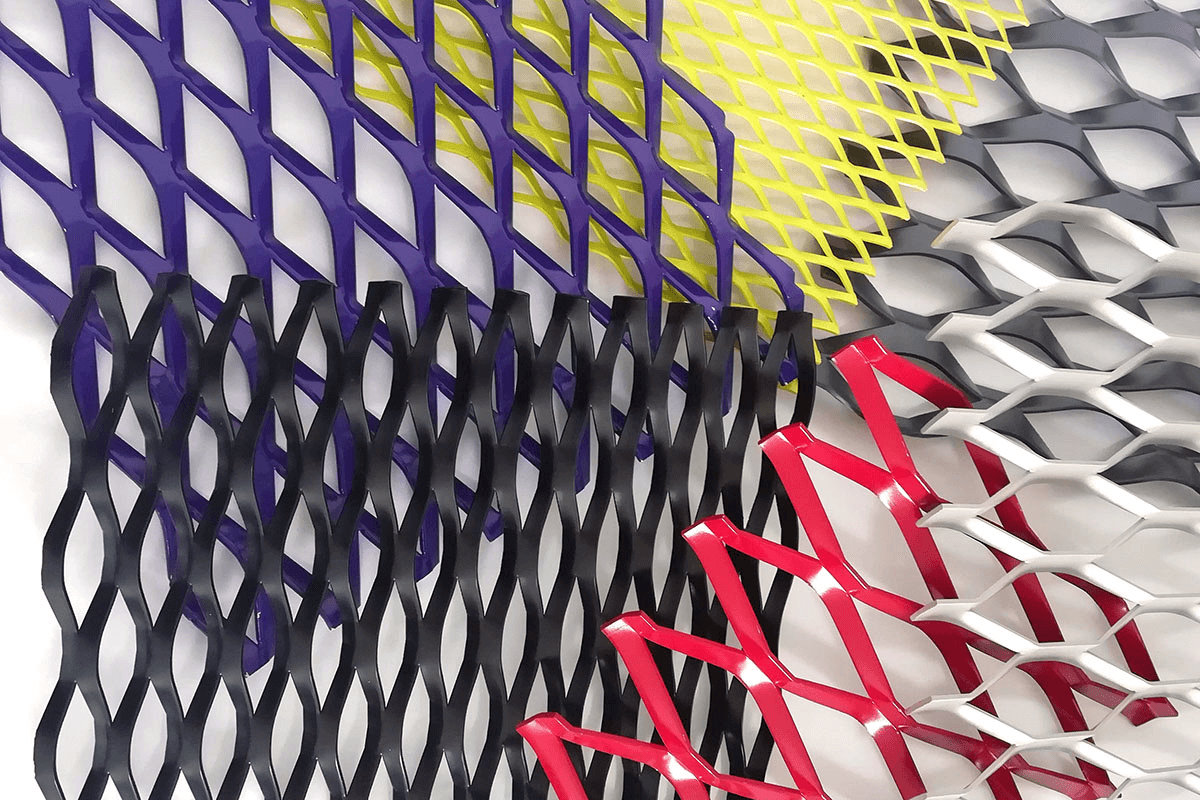

Expanded metal sheet is widely used in construction projects for façades, fencing, walkways, ceilings, partitions, safety guards, and architectural cladding. Its diamond-shaped mesh structure offers strength, ventilation, slip resistance, and aesthetic appeal. However, for building contractors, selecting the right expanded metal sheet is not always straightforward. Concerns about strength, flatness, corrosion resistance, installation compatibility, and long-term durability often create uncertainty during procurement.

Understanding these common issues—and choosing a manufacturer that can resolve them—directly impacts project efficiency, structural safety, and overall cost control.

Common Problems Contractors Face When Choosing Expanded Metal Sheet

1. Structural Strength and Load-Bearing Concerns

Because expanded metal sheet is formed by cutting and stretching a solid metal sheet, contractors often question whether the mesh structure can withstand wind loads, foot traffic, or mechanical stress. In façade or walkway applications, insufficient strength may lead to deformation or safety risks.

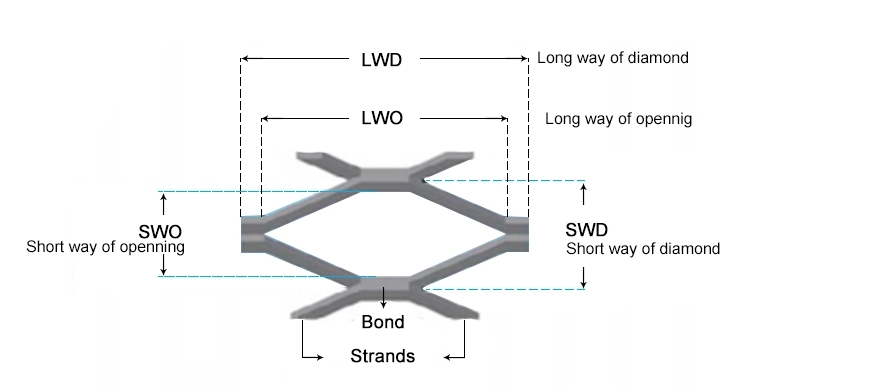

The key factors affecting performance include strand width, strand thickness, short way of diamond (SWD), and long way of diamond (LWD). If these parameters are not properly specified, the mesh may either be overdesigned (increasing cost) or underperform (compromising safety).

A reliable manufacturer must offer clear technical guidance to ensure the expanded mesh panels meet project-specific load requirements.

2. Raised vs. Flattened Expanded Metal Confusion

Expanded metal sheet is typically available in two forms: raised (standard) and flattened.

-

Raised expanded metal maintains the three-dimensional texture created during stretching. It offers excellent slip resistance and rigidity.

-

Flattened expanded metal is rolled to create a smoother surface, making it suitable for architectural and decorative applications.

Contractors sometimes struggle to determine which type is appropriate for their project. Using raised mesh in decorative cladding may cause installation challenges, while choosing flattened mesh for heavy-duty platforms may reduce slip resistance.

Clear product classification and application guidance are essential to avoid costly mistakes.

3. Corrosion and Environmental Suitability

Expanded metal sheet used in exterior construction must withstand weather exposure, humidity, pollution, and in some cases, coastal salt air. Selecting the wrong material may result in rust, staining, or structural degradation.

Common material options include:

- Carbon steel (economical but requires coating)

- Galvanized steel (improved corrosion resistance)

- Stainless steel (excellent long-term durability)

- Aluminum (lightweight and corrosion-resistant)

Contractors need a supplier capable of recommending the correct material based on environmental conditions and lifecycle expectations.

4. Dimensional Accuracy and Panel Flatness

Installation efficiency depends heavily on consistent dimensions and flatness. Poor manufacturing control can lead to uneven mesh openings, warped sheets, or inaccurate panel sizes. This results in on-site modifications, increased labor costs, and delayed project timelines.

Expanded mesh panels must maintain precise SWD, LWD, and strand alignment to ensure uniform appearance and structural consistency—especially in large architectural façades where visual continuity matters.

5. Supply Stability and Project Deadlines

Construction schedules are highly time-sensitive. Delayed material shipments can disrupt multiple stages of a project. Contractors often worry about inconsistent production capacity or unreliable export logistics.

A dependable expanded metal sheet manufacturer must have stable production lines, inventory planning, and international shipping experience to support large-scale construction projects.

How HIGHTOP Solves These Concerns

HIGHTOP provides engineered expanded metal sheet solutions designed to eliminate contractor uncertainty and reduce project risk.

Engineered Strength and Performance

HIGHTOP expanded metal sheet is produced through precise cutting and stretching processes that maintain structural continuity without welding or joints. This single-piece construction enhances rigidity and load distribution.

By offering a wide range of strand thicknesses, SWD, LWD, and open area ratios, HIGHTOP ensures contractors can select expanded mesh panels tailored to façade loads, walkway strength requirements, or decorative screening needs.

Clear Product Classification: Raised and Flattened Options

HIGHTOP supplies both raised and flattened expanded metal sheet with clear application guidance:

- Raised mesh for anti-slip walkways, safety platforms, fencing, and heavy-duty uses.

- Flattened mesh for architectural cladding, ceilings, partitions, and decorative screens.

This clarity helps contractors avoid specification errors and ensures optimal performance for each application.

Multiple Material Choices for Different Environments

HIGHTOP expanded metal sheet is available in:

- Low carbon steel

- Galvanized steel

- Stainless steel

- Aluminum

- Copper and specialty alloys

For outdoor architectural projects requiring corrosion resistance and long service life, stainless steel or aluminum expanded mesh panels are recommended. Galvanized steel offers a cost-effective balance for structural and fencing applications.

This material flexibility allows contractors to control budgets without compromising durability.

Precision Manufacturing for Easy Installation

HIGHTOP maintains strict dimensional control during production to ensure uniform mesh opening, accurate panel size, and excellent flatness. Expanded mesh panels can be cut, framed, or surface-treated according to project drawings, minimizing on-site adjustments.

Consistent geometry ensures seamless installation, especially in large façade systems where alignment is critical.

Stable Production Capacity and Professional Support

With more than 20 years of production experience, HIGHTOP supports large-volume orders with reliable lead times. Professional communication and export experience ensure smooth coordination from quotation to delivery.

Contractors receive technical assistance regarding mesh selection, thickness calculation, and surface treatment recommendations, helping them make confident purchasing decisions.

Conclusion

Selecting expanded metal sheet for construction projects involves more than choosing a diamond pattern. Contractors must evaluate strength, material suitability, surface type, dimensional accuracy, and supply reliability.

HIGHTOP expanded metal sheet addresses these concerns through engineered production, material diversity, precise dimensional control, and dependable project support. By partnering with HIGHTOP, building contractors reduce procurement risk, improve installation efficiency, and ensure long-term performance across architectural, structural, and safety applications.

Choosing the right expanded mesh panels is not just a material decision—it is a strategic step toward delivering safer, stronger, and more visually consistent construction projects.

Get in Touch

Please Email us via the contact form below, we will get back to you ASAP.