Expanded metal mesh is a staple in modern architecture, industrial safety, and infrastructure. Unlike woven or welded wire, it is manufactured by slitting and stretching a single metal sheet, creating a seamless, jointless diamond pattern. However, its performance—ranging from structural load-bearing capacity to visual transparency—is dictated by two critical geometric parameters: Short Way of Diamond (SWD) and Long Way of Diamond (LWD).

1. What are SWD and LWD in Expanded Metal?

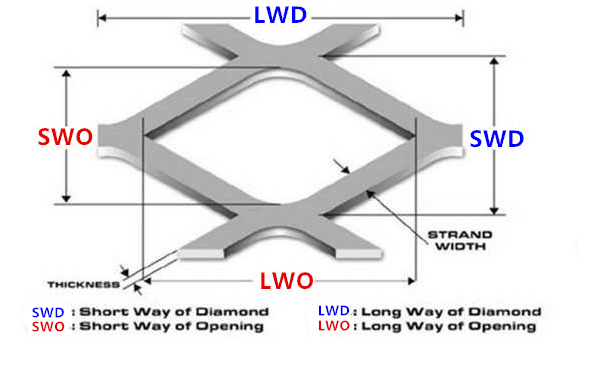

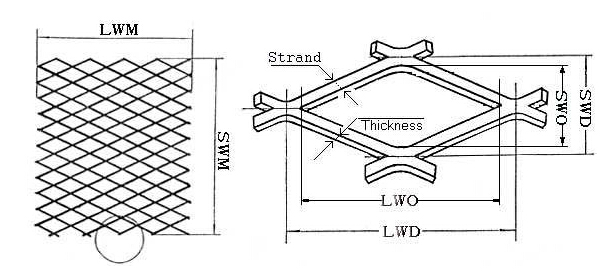

To choose the right mesh, you must first understand how these dimensions are measured. These parameters define the density of the material and the “openness” of the design.

-

Short Way of Diamond (SWD): The distance from the center of one node to the center of the next node across the short diagonal of the diamond.

-

Long Way of Diamond (LWD): The distance from the center of one node to the center of the next node across the long diagonal of the diamond.

Key Structural Components:

-

Strands: The individual metal strips that form the borders of the diamond.

-

Nodes: The solid intersections where the strands meet. These are the primary points of force transfer and structural integrity.

2. How SWD Influences Strength and Safety

The Short Way of Diamond (SWD) is the primary driver of the mesh’s mechanical performance.

- Density and Rigidity: A smaller SWD means more strands and nodes per square meter. This creates a dense, rib-like structure that excels at resisting bending and impact.

- Load-Bearing Capacity: If you maintain the same sheet thickness but decrease the SWD, the mesh becomes significantly stiffer.

- Safety Applications: Small-SWD meshes are ideal for industrial walkways, stair treads, and safety cages, as the tight pattern prevents small objects from falling through and provides better slip resistance.

3. How LWD Shapes Architectural Aesthetics

While SWD governs strength, the Long Way of Diamond (LWD) primarily dictates the visual “feel” and environmental performance of the panel.

Transparency and Ventilation

A larger LWD creates a more open structure. This increases visual permeability, making it the preferred choice for architectural facades where light and airflow are critical.

Visual Rhythms and Texture

- Small SWD/LWD: Creates a solid, opaque appearance from a distance, emphasizing the material’s texture.

- Large LWD: From a distance, the mesh “dilutes,” appearing as a semi-transparent veil or a series of rhythmic diagonal lines. This is a popular design choice for large-scale building envelopes.

Light and Shadow Patterns

The geometry of the LWD regulates how sunlight interacts with the building. Large-LWD patterns produce dramatic, shifting shadows throughout the day, adding a dynamic layer to architectural designs.

4. Balancing Technical Parameters in Real Projects

When specifying expanded metal, you must balance three conflicting goals: Function, Safety, and Budget.

| Project Priority | Recommended Configuration | Common Applications |

| High Strength / Safety | Small SWD (≤15mm), Thick Strands | Walkways, Grating, Fences |

| Architectural Impact | Large LWD, Aluminum or Stainless | Facades, Ceiling Panels |

| Privacy / Shading | Medium SWD/LWD, High Strand Width | Sunshades, Interior Screens |

5. Why Choose HIGHTOP Metal Mesh?

Selecting the right pattern requires a manufacturer capable of high-precision customization. HIGHTOP Metal Mesh specializes in engineered expanded metal solutions that bridge the gap between industrial utility and architectural beauty.

The HIGHTOP Advantage:

- Precision Tooling: Our advanced equipment ensures exact control over SWD, LWD, and strand geometry, maintaining pattern consistency across massive production runs.

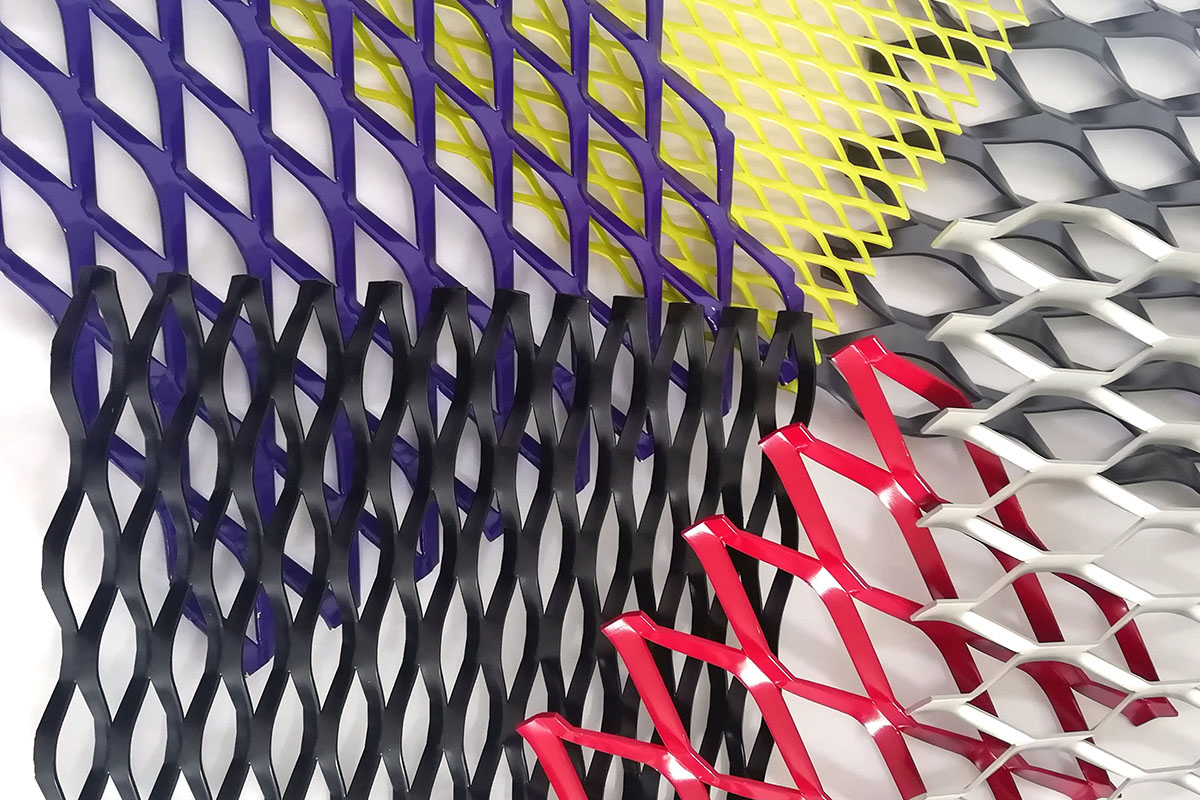

- Material Versatility: We work with carbon steel, aluminum, and stainless steel, offering various surface treatments like powder coating and anodizing for maximum durability.

- Technical Support: HIGHTOP provides expert guidance to help architects and engineers find the ideal balance between “open area” for aesthetics and “strand density” for safety.

- Global Efficiency: With three specialized factories and ISO 9001:2015 certification, we provide high-quality mesh with significant cost advantages and rapid delivery times.

In expanded metal design, SWD is the foundation of strength, while LWD is the regulator of light and sight. By understanding the interplay between these two dimensions, you can ensure your project is as safe as it is visually striking.

Would you like me to generate a technical specification table comparing common SWD/LWD ratios for different architectural applications?

Get in Touch

Please Email us via the contact form below, we will get back to you ASAP.