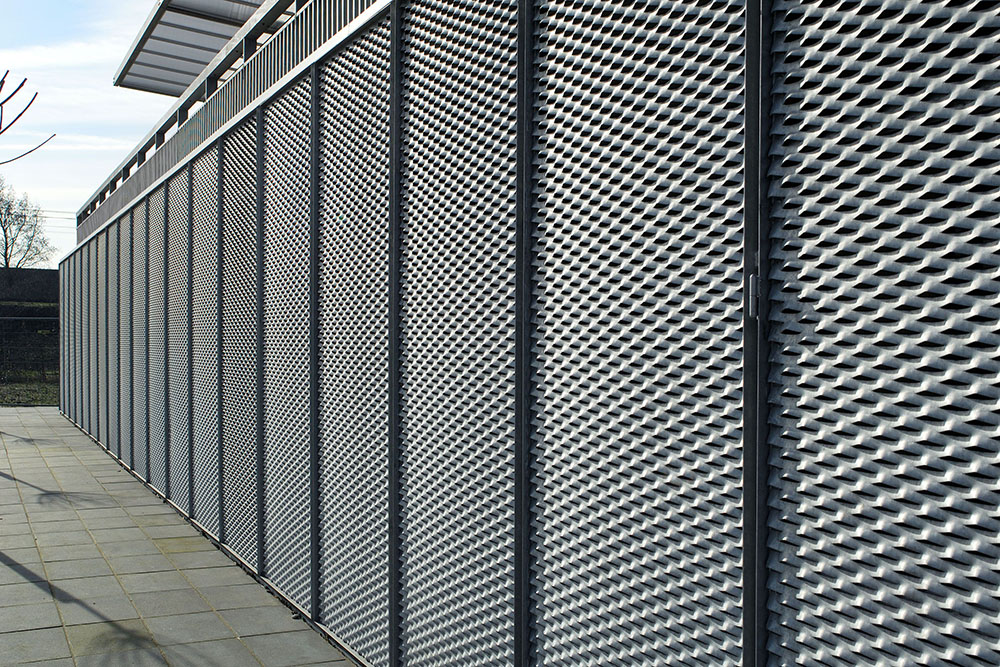

In modern industrial and commercial environments, fencing is no longer just a barrier—it’s an integral component of safety, ventilation, and operational efficiency. One of the most versatile and robust materials in fencing solutions is Expanded Metal. Characterized by its diamond-shaped openings and continuous construction, expanded metal delivers unmatched durability, adaptability, and longevity. This article explores the different material types used in expanded metal fencing and highlights why this solution is increasingly preferred across various industries.

I. What Is Expanded Metal?

Expanded Metal is created by simultaneously slitting and stretching a solid metal sheet, forming a rigid mesh with no welded joints. This one-piece structure offers exceptional mechanical strength and eliminates weak points often found in traditional fencing systems. The mesh design allows for excellent airflow, visibility, and light transmission, while still providing a strong physical barrier.

The true value of expanded metal fencing lies in its material flexibility. By using different base metals, the mesh can be tailored to specific performance needs, environmental conditions, and aesthetic preferences.

II. Stainless Steel Expanded Metal: High-End Corrosion Resistance

Stainless Steel Expanded Metal, particularly grades 304 and 316, is ideal for harsh or corrosive environments. It offers several key advantages:

- Corrosion Resistance: Stainless steel naturally forms a passive protective layer, making it resistant to rust, chemicals, and moisture. This makes it suitable for outdoor, coastal, or industrial applications.

- Clean Finish: With a polished surface, stainless steel meshes are visually appealing and hygienic, often used in pharmaceutical and food processing environments.

- Strength Under Pressure: High tensile strength enables it to withstand impact and deformation, ensuring long-term reliability for security fencing.

Use Case: Coastal warehouses or marine facilities where salt exposure and humidity would quickly degrade other materials.

III. Galvanized Steel Expanded Metal: Balanced Performance and Cost

Galvanized Expanded Metal offers a balance between performance and affordability. A layer of zinc is applied to steel, creating a barrier that resists oxidation and environmental wear.

- Economical Protection: Hot-dip galvanization provides long-lasting rust resistance without the premium cost of stainless steel.

- Lightweight Advantage: Lighter than solid metal panels, it reduces structural load while maintaining strength.

- Easy to Install: Galvanized panels are ideal for modular fencing systems due to their ease of handling and adaptability.

Use Case: Industrial fencing in inland facilities or construction sites that require long-term but cost-effective protection.

IV. Low-Carbon Steel Expanded Metal: Customizable and Colorful

Low-Carbon Expanded Metal, also known as mild steel expanded mesh, is widely used for its workability and customization options.

- Surface Coating Options: Powder coating or spray painting adds corrosion protection and allows for a wide range of colors (RAL standards), ideal for architectural integration.

- High Friction Surface: The mesh provides excellent grip, which is useful not only for fencing but also for walkways and platforms.

- Recyclability: Environmentally friendly and fully recyclable, low-carbon steel meshes meet sustainable building practices.

Use Case: Warehouse partitions and indoor fencing where design flexibility and color coding are essential.

V. Why Expanded Metal Outperforms Traditional Fencing

Compared to welded wire mesh, chain link, or solid panels, Expanded Metal fencing stands out for several reasons:

- No Welds, No Weak Points: The single-sheet structure enhances durability and reduces the risk of failure due to weld fatigue.

- Superior Impact Resistance: Expanded metal can absorb mechanical stress better, making it a top choice for high-security or high-traffic areas.

- Airflow & Visibility: Unlike solid barriers, it promotes ventilation and light passage while maintaining security, crucial in hot or enclosed spaces.

VI. HIGHTOP’s Custom Expanded Metal Fencing Solutions

As a leading manufacturer, HIGHTOP offers a full range of Expanded Metal fencing options customized by material, mesh size, thickness, and surface treatment. Whether you’re seeking corrosion-proof stainless steel fencing or a cost-efficient galvanized solution, HIGHTOP delivers:

- Wide Range of Materials: 304/316 stainless, galvanized steel, and mild steel—all available in multiple thicknesses.

- Mesh Customization: From fine micro-mesh to heavy-duty large openings for specific protection levels.

- Quick Delivery: Standard products are stocked, and custom orders can ship in 7–10 days globally.

Fencing is more than just a perimeter—it’s a statement of safety, efficiency, and design. By choosing Expanded Metal made from the right material for your specific application, you not only ensure long-term durability but also optimize functionality. Whether it’s stainless steel for extreme environments, galvanized steel for balanced protection, or low-carbon steel for flexible designs, expanded metal remains the top choice for modern fencing needs.

For long-lasting and customizable fencing solutions, trust HIGHTOP Expanded Metal—where strength meets precision.

Get in Touch

Please Email us via the contact form below, we will get back to you ASAP.