Expanded metal mesh is a highly versatile metal product widely used in architecture, industry, infrastructure, and safety systems. Created by cutting and stretching metal sheets into continuous mesh structures, expanded metal combines strength, durability, and functionality with an efficient use of material. With diamond-shaped or customized openings, expanded metal mesh is often referred to as metal diamond mesh and has become a preferred solution for both structural and decorative applications.

In this article, we explore the manufacturing process, material options, types, applications, and key advantages of expanded metal mesh, while also highlighting the importance of working with reliable expanded metal mesh manufacturers, expanded metal mesh suppliers, and an experienced expanded metal mesh factory.

What Is Expanded Metal Mesh?

Expanded metal mesh is produced by slitting and stretching metal sheets or plates without removing any material. This process creates a continuous mesh structure with interconnected strands and openings. Unlike welded or woven mesh, expanded metal mesh has no joints or welds, which enhances its structural integrity and load-bearing capacity.

Expanded metal mesh is available in various opening shapes, with diamond patterns being the most common. The unique structure provides excellent strength-to-weight ratio, making it suitable for a wide range of applications.

Materials Used in Expanded Metal Mesh

Expanded metal mesh can be manufactured from different metals depending on performance requirements and environmental conditions. Common materials include:

- Low carbon steel

- Galvanized steel

- Stainless steel

- Aluminum

- Copper

- Nickel

- Titanium

- Silver

Each material offers distinct advantages. For example, stainless steel expanded metal mesh provides excellent corrosion resistance, while aluminum expanded mesh panels are lightweight and suitable for architectural applications. Galvanized steel expanded metal mesh offers a cost-effective solution with enhanced rust protection.

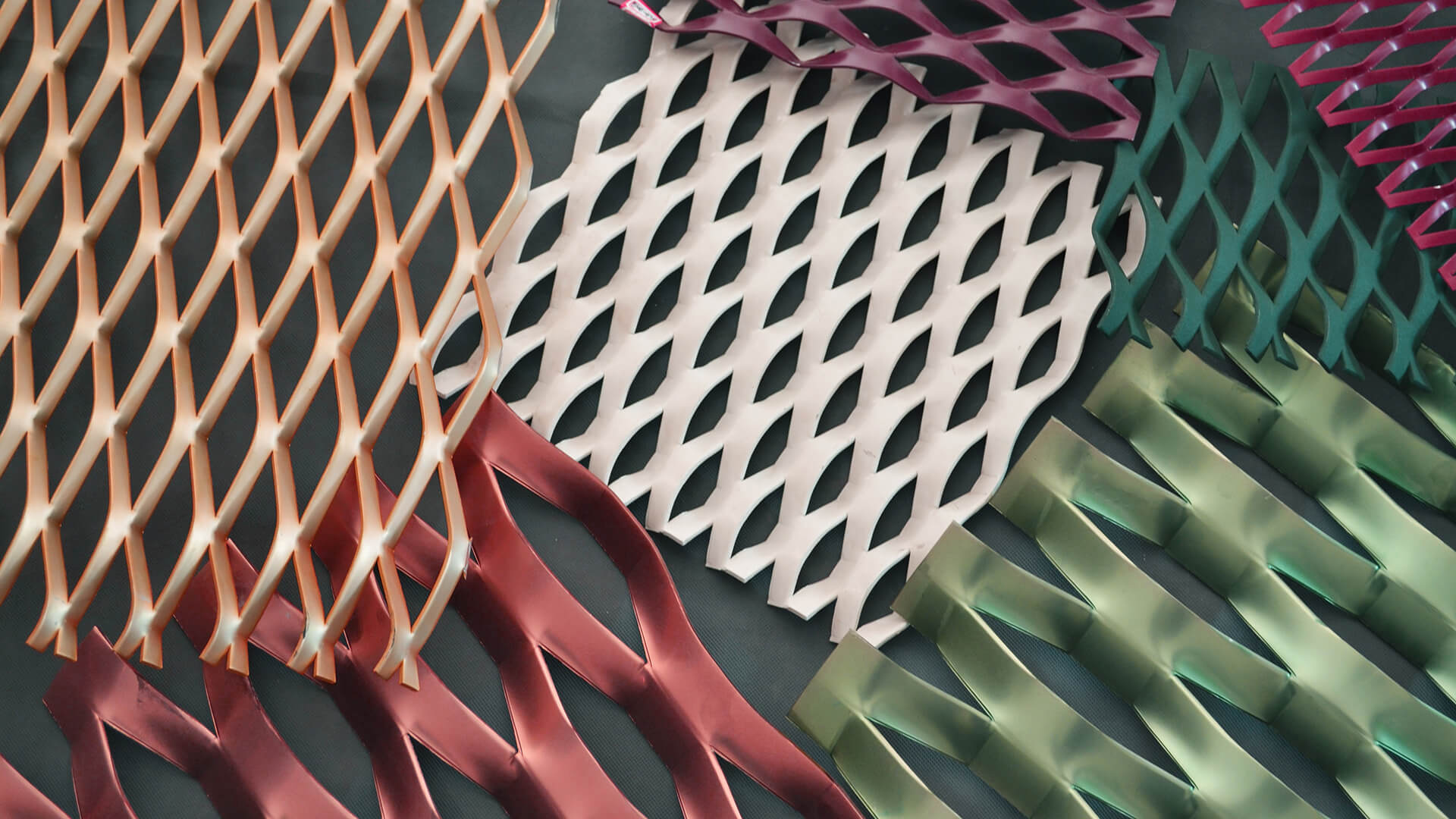

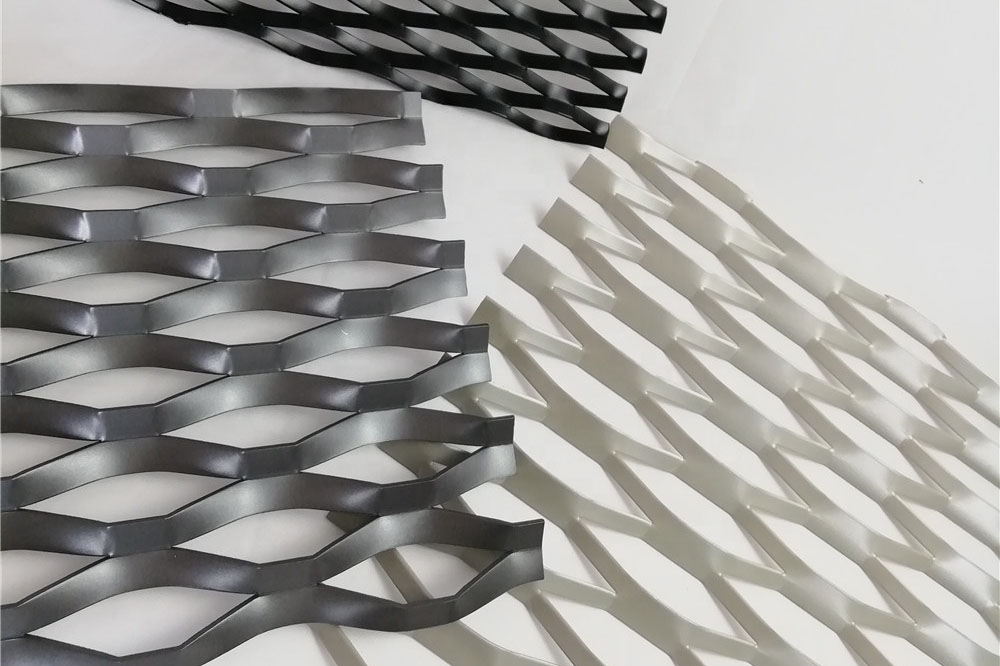

Types of Expanded Metal Mesh

Expanded metal mesh is generally classified into two main types based on fabrication methods:

Raised Expanded Metal

Raised expanded metal has a three-dimensional surface with visible strands and ridges. It offers enhanced rigidity and slip resistance, making it ideal for industrial platforms, stair treads, walkways, and safety applications.

Flattened Expanded Metal

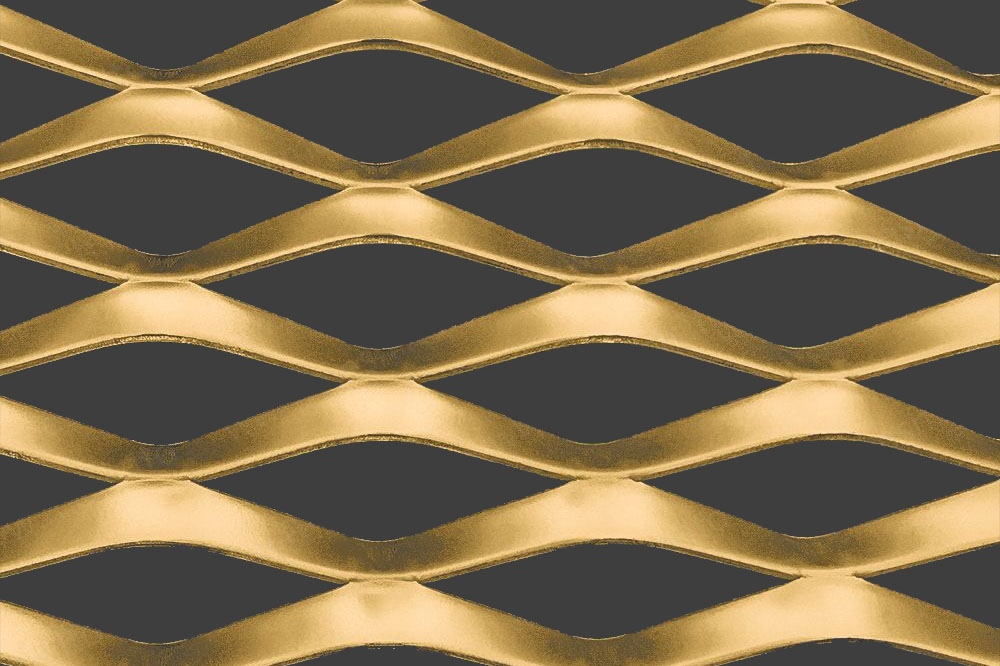

Flattened expanded metal is produced by rolling raised expanded metal through cold rollers. The result is a smooth and flat surface, which is suitable for decorative panels, facades, and architectural applications where aesthetics are important.

Both types are widely used in expanded mesh panels for structural, decorative, and protective purposes.

Key Advantages of Expanded Metal Mesh

1. High Strength and Durability

Expanded metal mesh is formed from a single metal sheet, which ensures structural continuity and superior strength. It can withstand heavy loads, impacts, and harsh environmental conditions.

2. Material Efficiency and Cost Effectiveness

The expanding process does not generate waste, as no material is removed. This makes expanded metal mesh a cost-efficient solution and an environmentally friendly choice.

3. Versatility in Applications

Expanded metal mesh can be used in a wide range of applications, including building facades, wall cladding, fencing, partitions, ceilings, screens, and decorative panels.

4. Safety and Anti-Slip Performance

Raised expanded steel mesh provides excellent anti-slip properties, making it suitable for walkways, bridges, stair treads, and industrial flooring.

5. Aesthetic Flexibility

With various opening sizes, strand widths, and surface finishes, expanded metal mesh can meet both functional and design requirements in architectural projects.

Applications of Expanded Metal Mesh

Expanded metal mesh is widely used across multiple industries:

Architectural and Decorative Applications

Expanded metal mesh is used for building facades, sunshades, wall cladding, partitions, metal screens, and ceilings. Designers appreciate its modern industrial aesthetic and functional benefits such as ventilation and light transmission.

Industrial and Infrastructure Applications

Expanded metal mesh is used for platforms, walkways, bridges, machine guards, and safety barriers. Its durability and load-bearing capacity make it suitable for heavy-duty environments.

Security and Protective Systems

Expanded metal mesh is commonly used in fences, protective enclosures, and security screens, providing both visibility and protection.

Commercial and Public Spaces

Expanded mesh panels are applied in shopping malls, airports, stadiums, and public buildings, where both aesthetics and structural performance are required.

The Role of Expanded Metal Mesh Manufacturers and Suppliers

Choosing reliable expanded metal mesh manufacturers and expanded metal mesh suppliers is critical for ensuring consistent quality, accurate specifications, and timely delivery. A professional expanded metal mesh factory should have advanced production equipment, strict quality control systems, and the ability to handle customized requirements.

Experienced expanded metal manufacturers can provide technical support, material recommendations, and customized solutions based on project needs. This is particularly important for large-scale architectural and industrial projects where precision and consistency are essential.

Why Work with Hightop Metal Mesh?

With over 20 years of production and export experience, Hightop Metal Mesh is recognized as a reliable partner in the expanded metal industry. The company offers a comprehensive range of expanded metal products, including raised and flattened expanded mesh panels in various materials and specifications.

Key advantages include:

- Advanced manufacturing processes and strict quality control

- Wide material options and customized solutions

- Stable production capacity and efficient delivery

- Professional technical support and responsive customer service

By working with an experienced expanded metal mesh factory, customers can ensure that their projects benefit from high-performance materials and consistent quality.

Conclusion

Expanded metal mesh plays a vital role in modern architecture, industry, and infrastructure due to its strength, durability, and versatility. From architectural facades and decorative panels to industrial platforms and safety systems, expanded metal mesh offers a reliable and cost-effective solution.

By partnering with professional expanded metal mesh suppliers, trusted expanded metal mesh manufacturers, and an established expanded metal mesh factory like Hightop Metal Mesh, customers can access high-quality expanded mesh panels tailored to their specific requirements. With its proven expertise and comprehensive product range, Hightop Metal Mesh continues to support global projects with durable and innovative expanded metal solutions.

Get in Touch

Please Email us via the contact form below, we will get back to you ASAP.