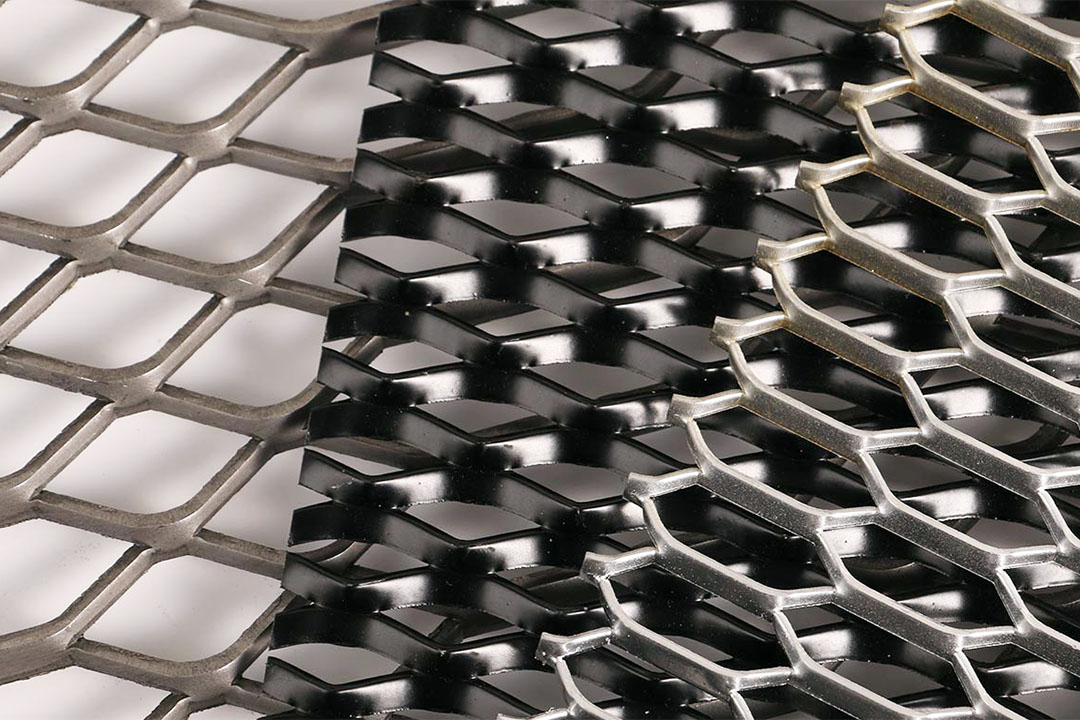

Stainless steel expanded metal is a high-strength, lightweight, and corrosion-resistant mesh product manufactured through CNC stamping and stretching. Using premium-grade 304 stainless steel as the standard material (18% chromium, 8% nickel) and optional 316L stainless steel for environments with higher chloride exposure, this mesh is engineered for exceptional durability and performance. Available in diamond, hexagonal, or circular openings, the mesh is formed by die stamping and biaxially stretching, resulting in a product that combines strength, functionality, and aesthetic appeal.

Technical Features and Specifications

Stainless steel expanded metal is offered in sheet thicknesses ranging from 0.5–8mm, with common sizes of 1.0, 2.0, and 3.0mm. Mesh pitch options range from 12.5mm to 200mm, accommodating both micro and macro applications. Standard sheet dimensions are 2000×1000mm, with customization available for unique projects. Surface treatments include electropolishing for enhanced corrosion resistance, sandblasting for improved friction, and brushed or mirror finishes for decorative use. These products comply with JB/T5979-92 and ISO4783/1-1990 standards.

Core Advantages

1. Weather Resistance and Chemical Stability

304 stainless steel withstands 500 hours of salt spray testing without red rust—far surpassing galvanized steel’s 72–120 hours. In petrochemical environments, its lifespan exceeds 8 years, while 316L stainless steel offers a 30% improvement in chloride corrosion resistance.

2. Mechanical Strength and Lightweight Design

With flexural stiffness 2–3 times higher than flat plates and 30% less weight, stainless steel expanded metal provides excellent load capacity. A 1mm sheet achieves tensile strength above 520MPa, compared to 300MPa for carbon steel. The diamond-shaped openings also provide natural anti-slip properties.

3. Multifunctional and Aesthetic

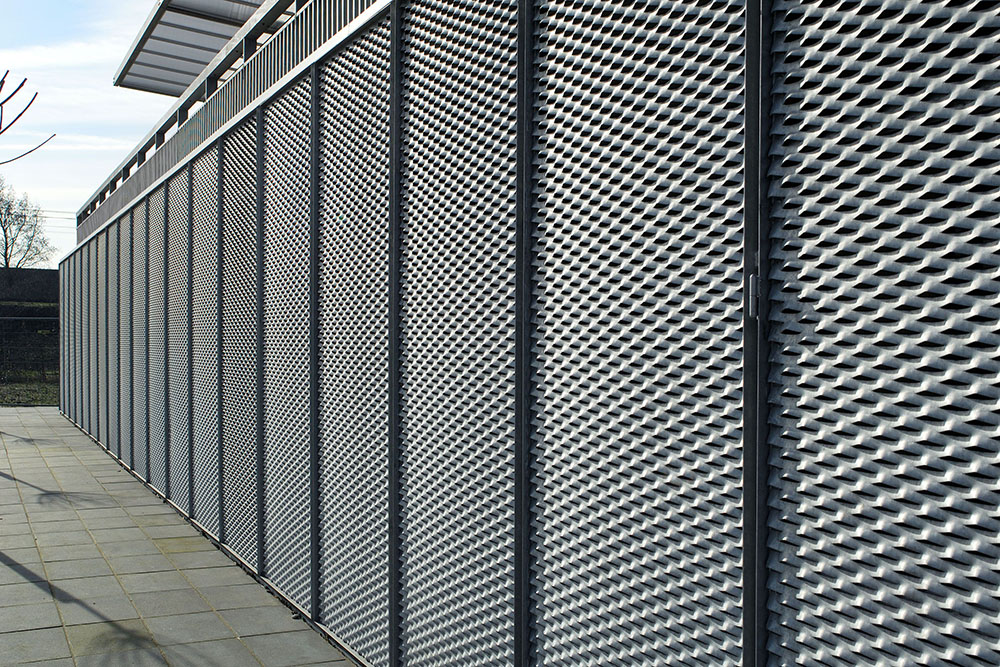

The mesh aperture can be optimized for specific applications: 0.5–2mm for heat dissipation, 5–10mm for architectural facades, and above 20mm for screening. Decorative finishes such as brushed and mirror polish enhance visual impact, making it suitable for prestigious projects like the Guadeloupe Palace of Justice.

4. Long Lifecycle and Sustainability

With a lifespan of 30–50 years—three times that of galvanized steel—stainless steel expanded metal reduces long-term costs and is 100% recyclable, lowering maintenance expenses by up to 40% over 15 years.

5. Ease of Processing

The mesh can be cut, bent, and welded without losing structural integrity. Its lightweight profile, at just 2.4kg/m² for a 1mm sheet, also reduces transport and installation costs.

Application Scenarios and Comparisons

1. Building Curtain Walls

Compared to glass curtain walls, stainless steel expanded metal lowers air-conditioning loads by 30% and prevents bird strikes, while being 80% lighter than concrete. It also offers three times the lifespan of zinc-steel guardrails.

Alternative issues: Galvanized steel requires frequent rust prevention; aluminum alloy grating has lower wind resistance and higher costs; glass curtain walls are fragile and expensive.

2. Industrial Platforms and Steps

It is 35% lighter than patterned steel, transmits light to prevent shadows, and offers five times the salt spray corrosion resistance of galvanized grating.

Alternative issues: Galvanized coatings degrade in coastal areas; engineering plastic mesh deforms under high heat.

3. Precision Filtration

316L stainless steel expanded metal withstands temperatures up to 870°C, avoids metal ion migration, and meets FDA standards.

Alternative issues: Nylon mesh cannot withstand high temperatures; perforated sheets may have burrs that contaminate products.

4. Other Uses

In environmental energy systems, it resists H₂S corrosion for 15 years. In transportation and agriculture, it reduces pedal weight by 40% and improves water permeability for seedling trays.

Cost Efficiency and Recommendations

A cost comparison for a 20 m² platform shows:

-

Stainless steel expanded metal: Initial cost ¥9,000 ≈ $1,260 USD, with no maintenance required.

-

Galvanized steel: Initial cost ¥3,000 ≈ $420 USD, but requires regular upkeep and earlier replacement — totaling ¥13,500 ≈ $1,890 USD over 20 years.

The stainless steel solution overtakes the cost advantage within 10 years and delivers long-term savings exceeding 50%.

Selection Guide for Stainless Steel Expanded Metal

| Application Area | Recommended Material & Grade | Thickness (mm) | Porosity / Pitch | Surface Finish / Features |

|---|---|---|---|---|

| Coastal / Chemical | 316L stainless steel | ≥ 2.0 | ≤ 30% porosity | High chloride resistance |

| Architectural | 304 or 316L stainless steel | 0.5 – 1.0 | 5 – 10 mm pore size | Mirrored finish for aesthetics |

| Industrial Platforms | 304 or 316L stainless steel | 4.0 – 6.0 | Short pitch ≤ 25 mm | Anti-slip, high load-bearing capacity |

| Precision Filtration | 316L stainless steel | 0.5 | Microporous mesh | Polished pore walls, FDA-compliant |

Stainless steel expanded metal combines exceptional corrosion resistance, structural strength, and versatility across industrial, architectural, and environmental applications. Compared to galvanized steel, aluminum alloy, and engineering plastics, it offers superior performance, longer service life, and better lifecycle cost savings. By selecting the right specifications and surface treatments, users can achieve optimal results for both functional and decorative projects.

Get in Touch

Please Email us via the contact form below, we will get back to you ASAP.